Water is an excellent heat transfer fluid, it is used to cool industrial processes and to generate steam for almost all thermal power generation. However, the use of water by itself can suffer from a number of problems, such as the corrosion of metals used in pipes, pumps and heat exchangers.

Therefore, heat transfer fluids based on aqueous mixtures are normally tested for their anti-corrosion properties using a combination of ASTM international standards. The most commonly referenced standards are:

- ASTM D-1384 – Standard Test Method for Corrosion Test for Engine Coolants in Glassware

- ASTM D-3306 – Standard Specification for Glycol Base Engine Coolant for Automobile and Light-Duty Service

Let’s delve deeper into what these standards mean and how they apply to anti-corrosion testing of water based (aqueous) heat transfer fluids…

ASTM D1384

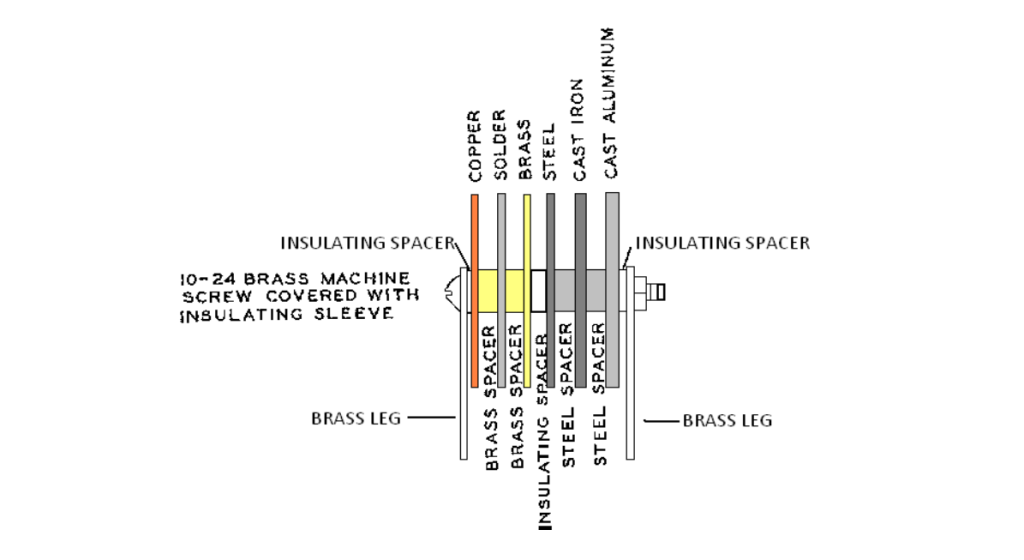

This standard defines the protocol for setting up glass laboratory equipment for the corrosion

testing of six specific metal coupons* (as per image below) in a mixture of 33 per cent of the heat transfer fluid to be tested, diluted with standard corrosive water, 67 per cent. The metal coupons are immersed in the solution, the mixture is aerated at 100ml/min air, and the entire test is carried out at 88oC for 336 hours (2 weeks).

This is clearly a tough test versus the conditions to which most heat transfer fluids (HTF) would be subjected to. However, it is the standard of testing that HTF customers expect. The ASTM D1384 methodology describes the way in which the coupons are arranged in the test fluid to allow some interaction to take place. The test pieces are separated by one insulator in the centre of the spindle holding the six coupons together, although the three soft metal coupons and the three iron-based coupons are in galvanic contact through metal spacers. The testing should be done in triplicate and the average of the three test coupon corrosion results should be reported.

ASTM D3306

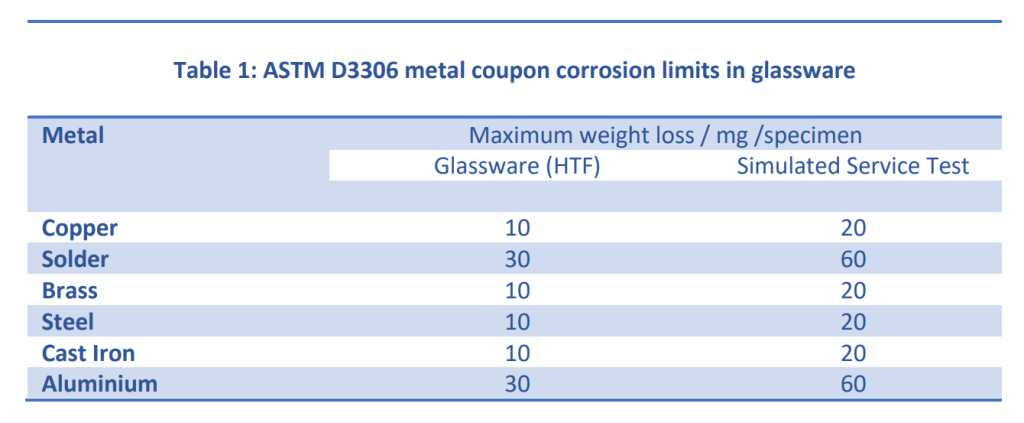

The measurement of coupon corrosion allowed in the ASTM D1384 test depends upon the method used as further described in ASTM D-3306 and shown in Table 1.

The simulated service test is used primarily for automotive applications. For heat transfer fluids, the glassware limits are used and any test run that gives weight loss for each metal less than the limit shown in Table 1 is deemed a pass.

*Metal coupons are small metal strips used to represent the pipes in the system. Within a test situation they are exposed to the fluid being tested for a set period then removed, cleaned, and weighed to calculate the corrosion rate. This helps determine how corrosive the heat transfer fluid is and how well it is protecting the system’s metal components.

Back to posts