It is clear that the careful selection of the right heat transfer fluid for the right application is essential for the best performance. As heat transfer fluids have unique properties and all commercial products will be formulated to a greater or lesser extent, to overcome some or all of the drawbacks of just using water alone.

In order to make the most of these fluids, the key design elements that need to be considered are:

Operational – over what temperature range does the heat transfer system need to operate and are there any times when the system may operate outside of these limiting values for an extended period? While a system may be designed to operate at specific temperatures, heat exchange surfaces, for example, may operate at much higher or lower temperatures. Is the fluid suitable to cope with these excursions in process conditions?

Process water – if make up water is required, to compensate for fluid losses, what are the necessary characteristics of that water and how could it affect the future system performance? All commercial formulated products are designed for specific purposes and will normally come with a recommendation for the quality of water required to maintain their integrity in use. If the water is too hard, for instance, the formulation may lead to solid precipitates and compromise corrosion protection or formulation stability.

Efficiency – over the lifetime of the system, what is the projected spend on the initial system installation, and how much is projected to be spent on energy to drive it? With most heating and cooling installations being capital intensive, it may be counterproductive if the system is not designed and sized to make the best use of the most efficient fluids available. For example, the use of propylene glycol solutions at low temperatures leads to an increase in viscosity that requires higher pumping power and hence higher cost compared with other fluids.

Materials – of what materials is the system built, and what is needed to ensure system operability and longevity? Raw glycols such as monopropylene or monoethylene glycol (MPG and MEG) are relatively unstable, leading to acidic breakdown products which may cause extensive corrosion. Formulated products are a must, and corrosion protection in use should be suitable for the duty required. Standards such as the ASTM D-1384 are designed to rigorously test the likely effect of product breakdown on the corrosion of common metal types.

Safety – is the fluid non-toxic and non-flammable? Ethylene glycol solutions are toxic to humans and other animals. Use of ethyl or methyl alcohol (methanol or ethanol) can lead to toxicity issues and flammability concerns. These issues can be critical in situations which deal with food or beverage processing with the potential for cross contamination due to loss of fluid containment. The use of inherently safe heat transfer fluids eliminates this risk.

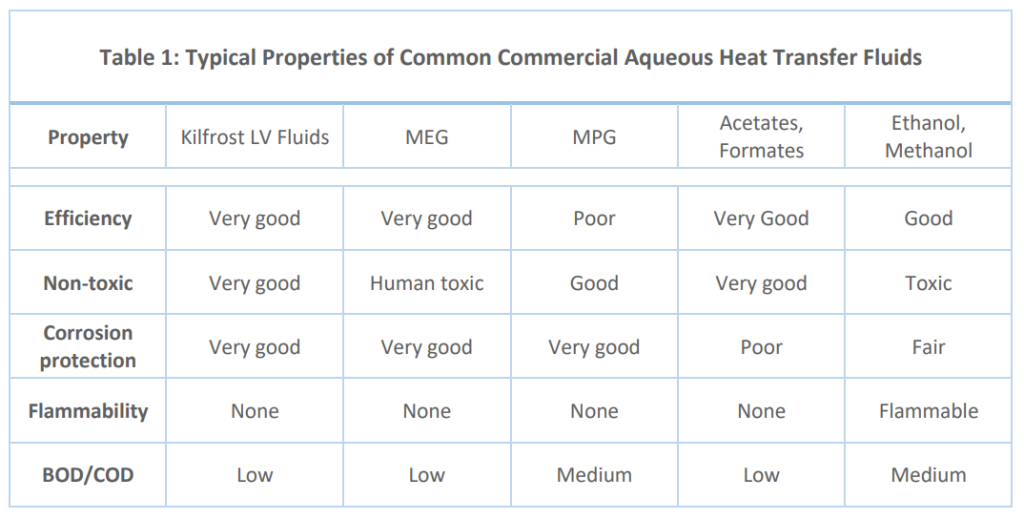

Operational design does bring together all elements of the intended use for the system. However, fluid performance is the workhorse of the system, so allowing for water quality and fluid attributes is key to ensuring efficient and risk-free operation. Manufacturers of commercial formulations are able to advise on water quality that will be preferable to use with their fluids. More generally, the following table summarises the common properties of common aqueous based heat transfer fluids.

For the above table, the following points should be noted:

Efficiency – a combination of low viscosity and high density. Having these properties in a fluid enhances heat transfer

Non-toxic – fluids based on ethylene glycol and methanol / ethanol have toxicity concerns.

Corrosion protection – commercial formulated products are normally tested with a stringent protocol, ASTM D-1384, and assessed using limits in ASTM D-3306.

Flammability – in addition to the toxicity concerns around ethanol and methanol, the potential for handling a flammable fluid or generating a flammable atmosphere above solutions of these products is present.

BOD – Biological Oxygen Demand is the oxygen required to biodegrade a fluid. This can take oxygen out of a water course if the fluid finds its way there and can lead to oxygen starvation of aquatic life.

COD – Chemical Oxygen Demand is a way to measure the ultimate oxygen needed for complete chemical breakdown.

Kilfrost ALV (advanced low viscosity) fluids have been designed to maximise the benefits, and to offer a risk-free option to customers who wish to use aqueous heat transfer fluids. Risk free, as the fluid is formulated with bio-derived base materials listed as GRAS (Generally Recognised as Safe) by the FDA and is classified as non-hazardous. Whilst Kilfrost ALV Plus, is certified by the US NSF as safe for incidental food and beverage contact, making it suitable for the food and beverage industry.

Explore our heat transfer fluids in more detail.

Back to posts