When it comes to ground and water source heat pumps and the use of heat transfer fluids, most companies are conscious of the impact of their operations and products may have on the environment. And despite rigorous controls, there is always a possibility of leakages or waste liquids coming into contact with water courses nearby.

Therefore, the key is to ensure these fluids have as little impact to the environment as possible if that situation occurs, either as part of a controlled permitted discharge or by minimising the risk of any accidental release.

Firstly, it’s important to cover that wastewater should not be discharged deliberately without first seeking consent or an environmental permit. These safeguards are in place to prevent harmful materials entering into, and adversely affecting, the receiving waters.

There are then a number of tests available to measure the potential impact of discharges into receiving waters, which includes BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) values, which is something we use to measure and demonstrate the environmental credentials of our fluid, but what do they mean?

BOD: Biochemical Oxygen Demand

BOD, put simply, is the amount of oxygen which is needed to decompose organic matter in a body of water by bacterial degradation.

The more oxygen used during decomposition (for example, in sewage or heavily polluted water), the less oxygen is available for fish and other aquatic life. This may lead to oxygen starvation of the water course and the various aquatic species. Hence, wastewater is often treated before being discharged, in part to lower the BOD, which is dependent on the consents and permits in place and the capability of the site.

These consents vary from location to location due to a variety of factors including population density, the quantity of waste, and the nature of the site. Testing the BOD value of a water sample takes five days and uses the introduction of certain specified bacteria to represent what would happen in nature.

COD: Chemical Oxygen Demand

COD is a measure of how much oxygen would be needed to completely oxidise the carbon in a sample.

For this test, sample which takes two or three hours, a strong chemical agent is introduced. The strong oxidising effect of the reagents in the COD test gives a more complete conversion of the substance tested and can be thought of as a maximum amount of required oxygen for chemical conversion.

In comparison, the BOD test gives an idea of how much oxygen would be required under normal biochemical (bacteriological) conditions.

Hence using the two measures provides…

BOD: how much oxygen is likely to be needed by bacterial decomposition of a substance in the environment.

COD: the maximum amount of oxygen required for full chemical degradation of the substance, which is usually higher than BOD.

How to apply BOD and COD measurements

BOD results on a sample will indicate how many milligrams of oxygen are being consumed within each litre of sample water in the environment. If this value is too high, then there is a danger that the fish within the water source will not have sufficient oxygen to survive.

If both the BOD and COD results are too high (accepted levels vary from country to country and region to region), this can indicate more serious pollution within a body of water. Depending on what has caused this pollution, there could be a very real risk to other animals and potentially humans too.

Minimising BOD and COD impact

Consents and environmental permits given to companies in relation to their waste discharge processes will typically outline BOD and COD limits and any other routine testing requirements, considering a number of factors, such as the location of the area and the population size. Any business with an environmental permit (including breweries and food/milk processors) must comply with the limits set down within that permit. If a limit is likely to be exceeded, then this must be reported to the appropriate Environment Agency, and the discharge not made.

Using process materials which have a lower BOD and COD level can mean that consents are easier to obtain, and further treatment of waste may not be required (which reduces the associated costs and infrastructure needs).

Exploring the BOD & COD of traditional glycol-based heat transfer fluids and Kilfrost GEO

Traditional glycol- and ethanol-based heat transfer products are biodegradable by more than 97 per cent in under five days. This biodegradability can lead to a high oxygen demand and therefore a high rate of BOD. This means that they are likely to have adverse impacts if released untreated into the environment.

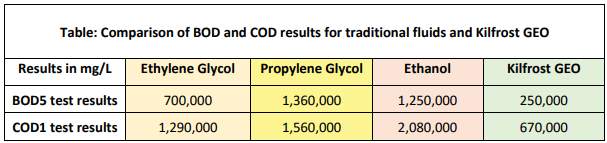

In contrast, some newer products feature more attractive BOD and COD profiles. Kilfrost GEO is a low viscosity heat transfer fluid, used in closed loop ground and water source heat pumps and is rapidly biodegradable and therefore the BOD and COD test results for Kilfrost GEO are significantly lower (up to 80 per cent lower in some tests) than traditional glycols. While any unintentional or untreated leakage of the product into the environment may still need to be reported to an Environment Agency, the impact based on lower BOD and COD values would be greatly reduced compared to that of traditional glycols.

Kilfrost GEO

Kilfrost GEO is an advanced heat transfer fluid that has been specifically engineered to improve the performance of closed loop ground and water source pumps.

As a non-toxic alternative to mono ethylene glycol (MEG), it offers first-of-a-kind protection that delivers an immediate increase in pumping and heat transfer efficiency – leading to significant long-term energy savings.

As well as offering superior performance, the product has unrivalled environmental credentials. It is classified as non-hazardous by CLP/REACH and is free from nitrates, nitrites, borates, heavy metals and phosphates.

Ready to learn more about our biodegradable fluid and the wider benefits it can have on your heat pump operations? Get in touch.

Back to posts